Difference between revisions of "Mining Critical Materials from Seawater and Brine"

| Line 19: | Line 19: | ||

[[File:4AIEDSM.png|778px]] | [[File:4AIEDSM.png|778px]] | ||

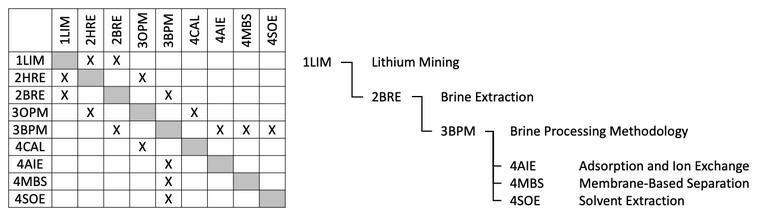

The 4AIE tree | The 4AIE tree extracted from the DSM above shows that brine extraction (2BRE) is one of the two lithium mining (1LIM) methods, and it requires some enabling technologies in brine processing methodology (3BPE). Adsorption and ion exchange (4AIE) is one of these promising Level 4 technologies, along with membrane-based separation (4MBS) and solvent extraction (4SOE). | ||

==Roadmap Model using OPM== | ==Roadmap Model using OPM== | ||

Revision as of 16:49, 1 October 2020

Technology Roadmap Sections and Deliverables

This is a technology roadmap for:

- 4AIE - Adsorption and Ion Exchange

Roadmap Overview

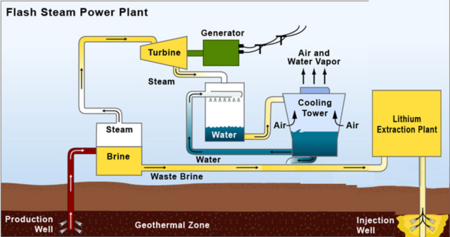

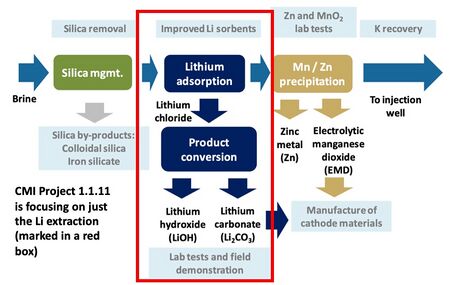

There are a variety of potential sources of lithium globally including minerals (e.g. clay, seawater, etc.); lithium-ion battery recycling; and saltwater brines (e.g. geothermal, continental, salt lakes, oil fields, etc.). We are focused on exploring lithium extraction from geothermal brines for a variety of reasons. One is that the concentration of lithium is higher in geothermal brines (approximately 300 ppm) than in other potential sources of lithium such as saltwater. Further, the Salton Sea in Southern California hosts a high concentration of lithium and is an attractive natural resource for the United States to take advantage of. Roughly 13 geothermal plants operate in this region with a combined electric generating capacity of 375 megawatts (MW), which together generate enough brine to recover a potential 200 metric tons of lithium per year - enough to supply the global demand for lithium. We are roadmapping a sorbent technology that extracts lithium from geothermal brines with a focus on how this technology can be applied to geothermal plants in Southern California. The two graphics below break out the schematic and R&D boundaries for the sorbent technology.

Concept of mineral extraction plant utilizing post-power production, pre-injection geothermal brine.<ref>Paranthaman, M. P., Li, L., Luo, J., Hoke, T., Ucar, H., Moyer, B. A., & Harrison, S. (2017). Recovery of lithium from geothermal brine with lithium–aluminum layered double hydroxide chloride sorbents. Environmental Science & Technology, 51(22), 13481–13486.</ref>

Schematic of R&D tasks.<ref>Paranthaman, M. P. “Lithium extraction from geothermal brine solution.” Webinar presented by the U.S. Department of Energy Oak Ridge National Laboratory.” 2018. Available at: https://iastate.app.box.com/v/cmi-webinar-november-2018</ref>

Design Structure Matrix (DSM) Allocation

The 4AIE tree extracted from the DSM above shows that brine extraction (2BRE) is one of the two lithium mining (1LIM) methods, and it requires some enabling technologies in brine processing methodology (3BPE). Adsorption and ion exchange (4AIE) is one of these promising Level 4 technologies, along with membrane-based separation (4MBS) and solvent extraction (4SOE).

Roadmap Model using OPM

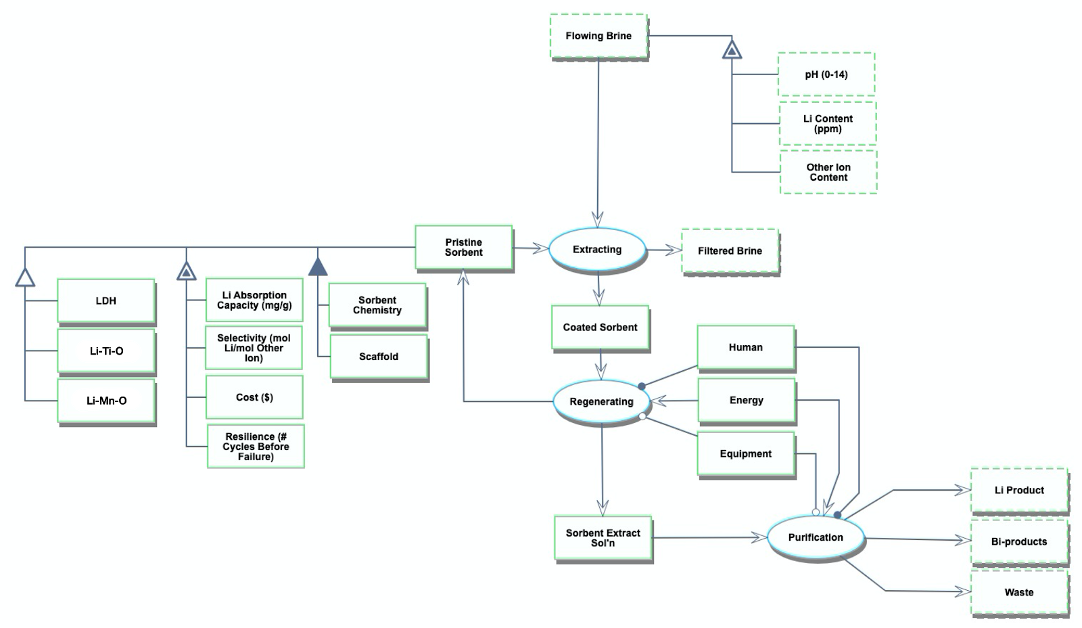

The Object-Process-Diagram (OPD) of the 4AIE roadmap is shown in the figure below. This diagram captures the main object of the roadmap (sorbent), its various instances including Lithium Manganese Oxides (Li-Mn-O), Lithium Titanium Oxides (Li-Ti-O), Lithium Aluminum Layered Double Hydroxide (LDH) Chloride; and its characterization by Figures of Merit (FOMs).

Figures of Merit

| FOM Name | Unit | Description |

|---|---|---|

| Adsorption capacity | [mg/g] |

|

| Selectivity | [dmnl] |

|

| Lithium Production Cost | [$/kg] |

|

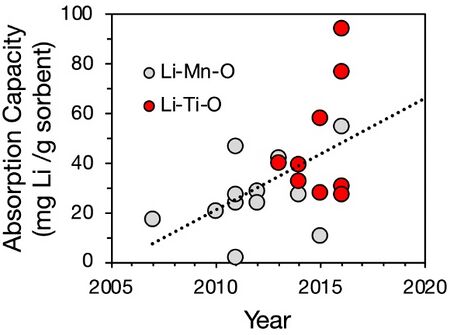

We gathered reported data from 21 peer-reviewed publications within the Li brine extraction literature to generate a plot of sorption capacity. Note that we provide data for only 2 of the 3 sorbents identified in our roadmap OPM (Li-Mn-O and Li-Ti-O), as there are few reports of sorbent capacity for lithium aluminum layered double hydroxide chloride (LDH) sorbent.

Adsorption capacities of major sorbents.<ref>Li, L., Deshmane, V. G., Paranthaman, M. P., Bhave, R., Moyer, B. A., & Harrison, S. (2018). Lithium recovery from aqueous resources and batteries: A brief review. Johnson Matthey Technology Review, 62(2), 161–176.</ref>

References

<references />