Difference between revisions of "Autonomous Mobile Robots for Enhancing Warehouse Logistics"

Jump to navigation

Jump to search

| Line 3: | Line 3: | ||

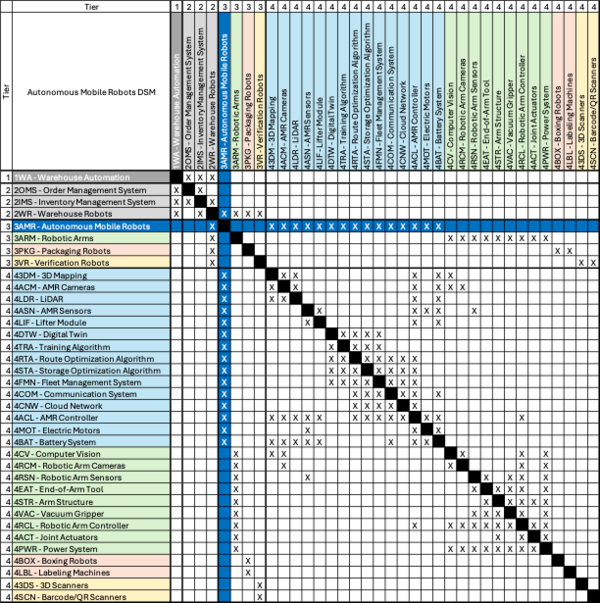

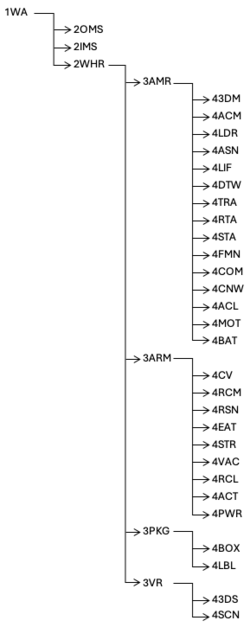

=Design Structure Matrix (DSM) Allocation= | =Design Structure Matrix (DSM) Allocation= | ||

We present here the DSM allocation of Autonomous Mobile Robots and its tree. | We present here the DSM allocation of Autonomous Mobile Robots and its tree. We can see that the company-wide initiative of Warehouse Automation, which comprises Order Management System, Inventory Management System, and Warehouse Robots. | ||

[[File:3AMR_DSM_v02.png|600px]] [[File:3AMR_tree_v01.png|250px]] | [[File:3AMR_DSM_v02.png|600px]] [[File:3AMR_tree_v01.png|250px]] | ||

Revision as of 22:26, 9 October 2024

Roadmap Overview

Design Structure Matrix (DSM) Allocation

We present here the DSM allocation of Autonomous Mobile Robots and its tree. We can see that the company-wide initiative of Warehouse Automation, which comprises Order Management System, Inventory Management System, and Warehouse Robots.

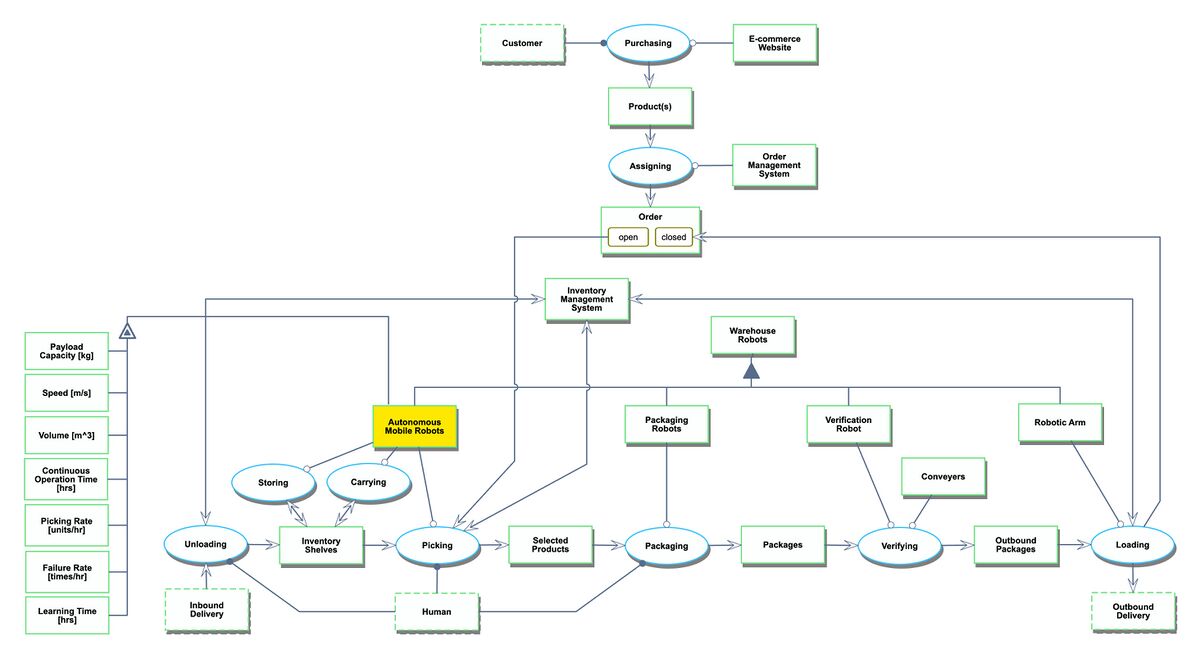

Roadmap Model using OPM

Figures of Merit (FOM)

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Payload Capacity | [kg] | Total weight the AMR can carry (including items and shelves) |

| Speed | [m/s] | Average speed of the AMR while carrying shelves inside the warehouse |

| Volume | [m^3] | Volume of AMR (width x length x height) |

| Continuous Operation Time | [hrs] | Total time the AMR can operate in one full charge |

| Picking Rate | [units / hr] | Number of units the AMR can assist the picker to pick per hour |

| Failure Rate | [times/ hr] | Number of times the AMR fails per hour |

| Learning Time | [hrs] | Total time it takes to train the AMR to operate in a warehouse |